- Home

- Manufacturing

- PLM Integration

PLM Integration for Dynamics 365

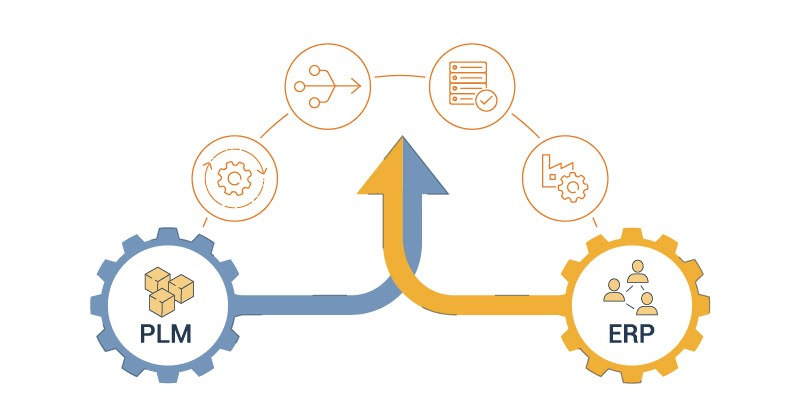

Seamlessly connect any PLM, CAD, and PDM systems to Microsoft Dynamics 365 with no-code, bidirectional integration.

Break down silos and accelerate time to market with STAEDEAN’s no-code integration solution embedded in Microsoft Dynamics 365 F&SCM. In just 3 weeks, eliminate manual workflows and unify data from PLM, CAD, and PDM systems directly within Dynamics 365. As the original creators of the Engineering Change Management (ECM) module, now part of Microsoft Dynamics, we bring 20+ years of expertise to deliver bidirectional integration with version control, automated workflows, and secure product release management.

Experience our PLM-ERP integration solution firsthand

Book your free demo today

Achieve faster time-to-market by removing data silos

To outpace the competition, manufacturers must quickly bring high-quality products to market. This is often hindered by poor integration and collaboration between engineering and manufacturing teams working across different systems.

STAEDEAN's PLM integration for Dynamics 365 offers guided workflows, streamlines data movement, enhances collaboration, and ensures real-time data sharing—all within a single source of truth for efficient production.

Our flexible PLM Integration Framework connects any PLM, PDM, or CAD system with Microsoft Dynamics 365 Finance & Supply Chain Management. We provide ready-to-use templates for Siemens Teamcenter and PTC Windchill, along with compatibility for systems like 3DX Dassault, Oracle Agile, Ansys, and Vault. It's a proven, scalable solution that ensures data quality, validation, and ownership.

Key Challenges

Prolonged time to market

Revenue loss and production rework

Inconsistent, low-quality data management

Key Features

Scroll to

Bi-directional Integration

Our bi-directional PLM-ERP integration flexibly connects diverse data sources—flat files, XML, Azure Blob Storage, web services, and more. It enables real-time data exchange and complex system interactions with visibility into inventory, vendors, and costs.

Suitable for Any PLM System

With our robust, user-friendly point-and-click integration framework, you can integrate any PLM, PDM, or CAD system with Microsoft Dynamics 365 F&SCM. The integration enables swift and flexible attribute mapping between D365 and your chosen PLM.

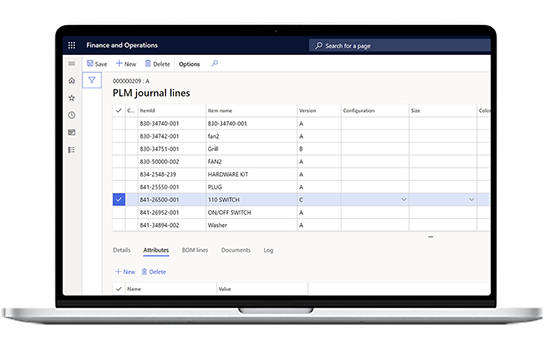

Automate data transfer

The PLM-ERP integration automates all the processes around product data movement, such as importing and exporting between PLM and Dynamics 365, ensuring data quality, validating product data, controlling master data in real time, and managing product versions and releases.

Benefits

Explore our PLM Integration for Dynamics 365

STAEDEAN's PLM integration is a cutting-edge solution embedded in Microsoft Dynamics 365 Finance and Supply Chain Management. Discover how it can streamline workflows, simplify product lifecycle management, and boost efficiency.

Key Functionalities

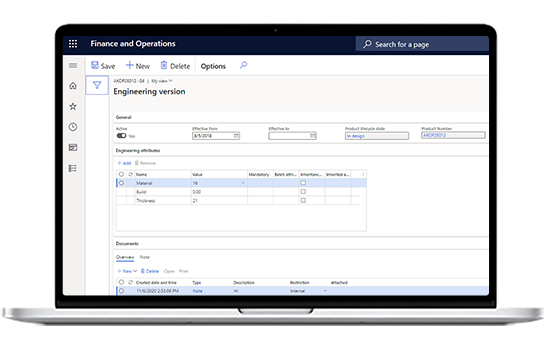

Change Management

Change Management

Tracks design changes and manages version revisions across the entire product lifecycle. Ensures that all changes are communicated across teams to maintain consistency.

Data Synchronization

Data Synchronization

Transfers validated data seamlessly and maintains a single source of truth.

BOM Management

BOM Management

Transfers large BOM automatically and manages change order processes.

Product Lifecycle Management

Product Lifecycle Management

Connects PLM and ERP to manage product lifecycle from design to production.

Workflow Management

Workflow Management

Streamlines design and manufacturing processes to avoid duplicate manual work and optimize workflows.

Data Insights

Data Insights

Industries we serve

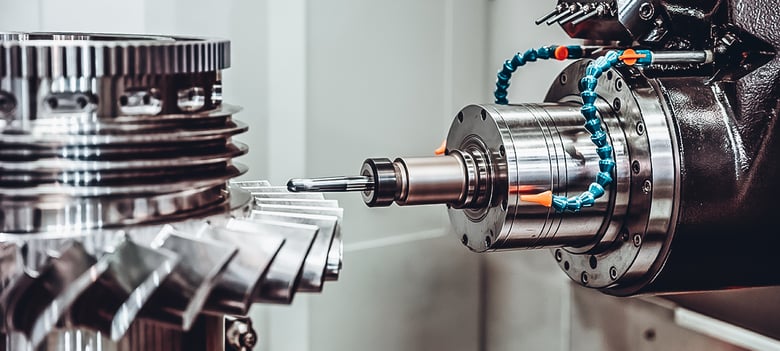

Industrial Machinery and Manufacturing

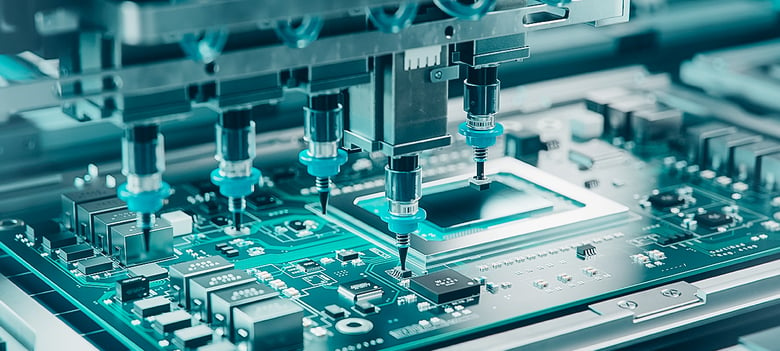

Electronics and Technology Manufacturing

Aerospace and Defense

Battery and Electric Vehicles Manufacturing

Frequently asked questions

What kind of data can I integrate with the PLM integration for Dynamics 365?

Our solution provides a bidirectional integration between any PLM, PDM, or CAD system and Microsoft Dynamics 365 F&SCM. This ensures smooth two-way data exchange, preserving master data integrity.

With support for modern connectors like flat files, XML, Azure Blob Storage, file shares, and web services, our integration offers unmatched flexibility. You can efficiently transfer key data from PLM to ERP, such as BOMs, part data, product statuses, engineering documents, and attributes. Data movement from ERP to PLM includes on-hand inventory, vendor details, engineering versions, and transactions, keeping both systems in sync.

Can I treat data that comes from the PLM system differently when in ERP? (selected use of change management)

Yes, you can treat PLM data differently in the ERP. With our ‘change management’ functionality, you can control and manage PLM and ERP data based on your requirements.

Is ECM a prerequisite for PLM Integration for Dynamics 365?

Yes, engineering change management (ECM) is the basis of PLM integration. ECM manages product/version changes, and variances on bills-of-material, routings, and inventory. To yield great results, Engineering Change Management should first be implemented in the Microsoft Dynamics 365 system.

I have a messy PLM System - Can I connect to ERP?

Yes, you can, provided your engineering data quality is good. In case of poor quality, data needs to be manually corrected in the ERP system, which can slow down the process and significantly increase the implementation time.

What's the implementation time for PLM integration?

The PLM integration for Dynamics 365 can be implemented in as little as 3 weeks once governance, responsibility, and data ownership are defined by engineering and manufacturing functions.

How do I select a PLM integration for my business?

The right PLM integration for Dynamics 365 is crucial to avoid costly rework. Learn the factors to consider when selecting PLM integration, from gap analysis to calculating ROI, in our comprehensive guide.

Does STAEDEAN provide PLM Integration only with Microsoft Dynamics?

Yes, we provide PLM integration with Microsoft Dynamics 365 Finance & Supply Chain, AX, and Dynamics 365 Business Central.

Resources

Scroll to

Eric Van Hofwegen

Eric Van Hofwegen

Peter van Leeuwen

Peter van Leeuwen