Manage delayed maintenance with DynaRent

Michiel Toppers

Michiel Toppers

Table of contents

Service management software is getting better and better. As a result companies forecast equipment maintenance scheduling and streamline corrective or emergency maintenance issues get better too. The offshoot of strong service management strategy and execution is that companies actually have more freedom. They can now prioritize service needs and allocate tasks like cleaning or extra performance checks to a delayed maintenance schedule. Even thought it is a great development. You still need to be sure that your software helps you take care of delayed maintenance as well. It is just as important as taking care of other service needs.

DynaRent work hand in glove with Microsoft Dynamics 365 for Finance and Operations and Microsoft Dynamics AX. Register equipment for delayed maintenance and it incorporates correctly in you service schedule. No detail falls through the cracks across your equipment lifecycles. Delayed maintenance is part of the real-time knowledge base about your equipment. And it is fully integrates with your ERP system.

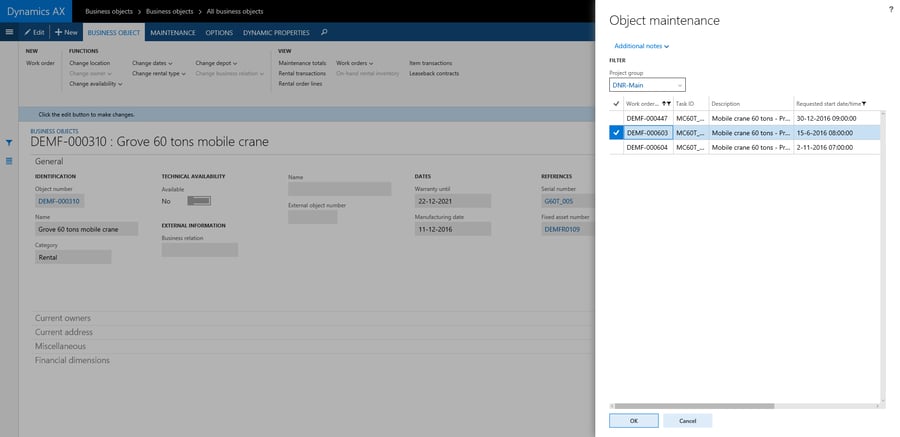

Image 1: Complete delayed maintenance overview per piece of equipment

DynaRent includes delayed maintenance and future maintenance options. It also has the ability to monitor such tasks for every piece of equipment that your register for service. Look for example at the creation of ad-hoc maintenance or corrective maintenance work orders. In addition, DynaRent automatically informs service planners about any outstanding maintenance tasks. That is including information and alerts. So it helps them decide to add tasks to the ad hoc maintenance that’s going to be executed.

With a few clicks, service planners can schedule service jobs. And create work orders that include every piece of data that service engineers will need. Furthermore, for an ad hoc job that includes delayed maintenance tasks. While of course you can incorporate delayed maintenance into your predictive maintenance schedule. The ability to combine ad hoc and delayed maintenance at any time keeps your business as lean and efficient as possible. This is the kind of flexibility that companies want and need for equipment service management. Especially in a customer-focused marketplace that runs on tight margins.

DynaRent’s automation and rich database of integrated information enables planners, engineers, and your back office to work together organically. That goes for predictive, corrective, and delayed maintenance. The most complex work orders can be generated in seconds. And when service engineers complete them, all information is updated instantly in ERP, for billing and equipment lifecycle management updates.

Image 2: Easily include delayed maintenance and all its information in current periodic or predictive maintenance work orders.

Curious? Contact us for a demonstration tailored to your needs.